This brake pad is compatible with following systems:

SRAM

- SRAM Apex 1

- SRAM CX1

- SRAM Etap HRD

- SRAM Force 1

- SRAM Force 22

- SRAM Red 22 (B1)

- SRAM Rival 1

- SRAM Rival 22 HRD (B1)

- SRAM 700 B1 HDR

- SRAM S900 HRD

- SRAM Level Ultimate (model year 2017-2019)

- SRAM TLM A1 (model year 2017-2019)

- SRAM Red eTap AXS for Red Flatmount Monoblock brake calipers) - ATTENTION: is often confused with the SRAM Red eTap AXS Force Flatmount 2-Piece brake pads , which are not compatible because they have a different attachment.

Each set includes pads and a spring to replace the brake pads on one caliper.

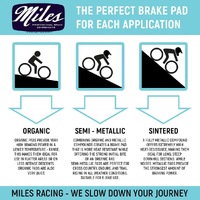

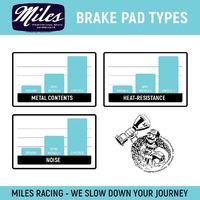

Different Types of Disc Brake Pad Compounds

Typically you'll find that there are three types of compounds to choose from when buying new brake pads for your disc brake equipped bike. They are:

- Organic

- Semi-Metallic

- Sintered

Each of these brake pad compounds will provide a different feel during braking. You'll also find that one compound may last longer compared than another depending on the type of rider you are and the amount to which you use your brakes.

What compound should I choose?

Choosing a compound ultimately depends on the type of riding you are doing. In most cases a semi-metallic pad will exceed the needs of most riders because it combines the durability of sintered with the feel of organic compounds. To make sure you're getting the best pad for your riding style, review the benefits of each below.

Semi-Metallic Brake Pads

Semi-metallic brake pads are an all-round solution for most common conditions, where brakes are not getting extremely hot. They work best for dirt jumping, cross country and lighter enduro rides with shorter downhill segments. They'll even be more than capable for downhill riders who aren't standing on the brakes all the way down, or for lighter riders.

With a high percentage of iron and copper added to the resin in the compound, semi-metallic pads offer a longer life and more heat resistance compared to organic disc brake pads. The metal compounds add longevity and the resin allows for the pad to have high friction against the brake rotor right away.

Because of this, you'll notice semi-metallic brake pads have a stronger initial bite when you begin to pull the brake lever. If you prefer your brakes to grab and feel strong from the start, semi-metallic pads should be your first choice.

| SEMI-METALLIC PAD PROS | SEMI-METALLIC PAD CONS |

| - Great initial bite | - Wears faster than sintered |

| - Easy to break-in | - Not ideal for adverse conditions (wet, mud, etc.) |

| - Quieter |

Sintered Brake Pads

Sintered pads, also known as metal or metallics, are brake pads that are completely made up of hardened metal, bonded together with high heat and pressure. There are no resins present in sintered brake pads making them much more durable than a semi-metallic or organic pad.

Sintered disc brake pads are perfect for larger riders, braking on steeper descents, or riders who have had to deal with brake fade issues. While the initial bite of sintered brake pads are not as strong as semi-metallic or organic compounds, they can handle way more heat.

Sintered brake pads also provide a more consistent feel and can be easily modulated, giving your brakes a progressive feel at the lever, rather than only being on or off.

Sintered pads also shine across a wider range of conditions. They are less likely to be effected by dust, mud, or water than other pad types.

| SINTERED PAD PROS | SINTERED PAD CONS |

| - Longer lifespan | - Longer break-in period |

| - Work better in all conditions | - Lower initial bite |

| - Fade at higher temperatures |

(MI-PAD-68)

VERSATILE, ALL-WEATHER USE: Semi-metallic brake pads are best suited for daily urban rides, dirt, XC, E-bikes, trail and light enduro rides, where bikers are not pumping on their brakes continuously. Rides are more fun with the smooth and effortless braking mechanism. Enjoy quieter rides and less rotor wear compared to sintered counterparts.

PREDICTABLE PERFORMANCE: Bikers have the benefit of significantly better brake performance compared to organic brake pads. You have better peace of mind with consistent and stable performance to cover a wide range of applications. Semi-metallic brake pads tend to function better in colder riding conditions.

PRICE-PERFORMANCE RATIO: Semi-metallic brake pads offer the benefit of a comfortable, firmer brake pedal feel. They are a valuable solution to bikers who are looking for a safe, durable braking solution that does not break their budget.

DURABLE: Durable metallic construction along with Kevlar additive makes these brake pads long-lasting. Special iron and copper compound formulation gives better resistance to heat.

RELIABILITY & COMPATIBILITY: Experience highly reliable, fade-free braking performance on road bikes, touring bicycles, e-bikes, e-MTB cycles, and low impact mountain bikes. Non-asbestos construction further ensures biking safety. Made in Germany and tested by independent testing companies. Check the list of compatible brake systems for a complete list of compatible brakes.

Compatibility

These replacement SRAM brake pads can be used in the following:

SRAM

- SRAM Apex 1

- SRAM CX1

- SRAM Etap HRD

- SRAM Force 1

- SRAM Force 22

- SRAM Red 22 (B1)

- SRAM Rival 1

- SRAM Rival 22 HRD (B1)

- SRAM 700 B1 HDR

- SRAM S900 HRD

- SRAM Level Ultimate (model year 2017-2019)

- SRAM TLM A1 (model year 2017-2019)

- SRAM Red eTap AXS for Red Flatmount Monoblock brake calipers) - ATTENTION: is often confused with the SRAM Red eTap AXS Force Flatmount 2-Piece brake pads , which are not compatible because they have a different attachment.

| SKU | MI-PAD-68 |

| Brand | Miles Racing |

Usage Tips:

To get the most braking power out of your new semi-metallic pads, it is important to follow these steps to break them in properly.

- Brake for 5 seconds while riding at a speed of about 7 mph. Repeat this process 3 more times.

- Brake from about 20 mph with medium power and release before coming to a complete stop. Repeat this process 20-30 times. You should feel the brake performance increase. Let the pads cool between each stop.

- Done - Ready for action!

Attention: To avoid glazing, sintered brake pads need a running in time without heat development. The first 200 brake applications should get done controlled under lower speed. This process helps to roughen up the surface of the friction material. Because of the high metal portion, sintered brake pads need a disc with bigger holes on the braking surface, to keep the surface of the friction material rough.